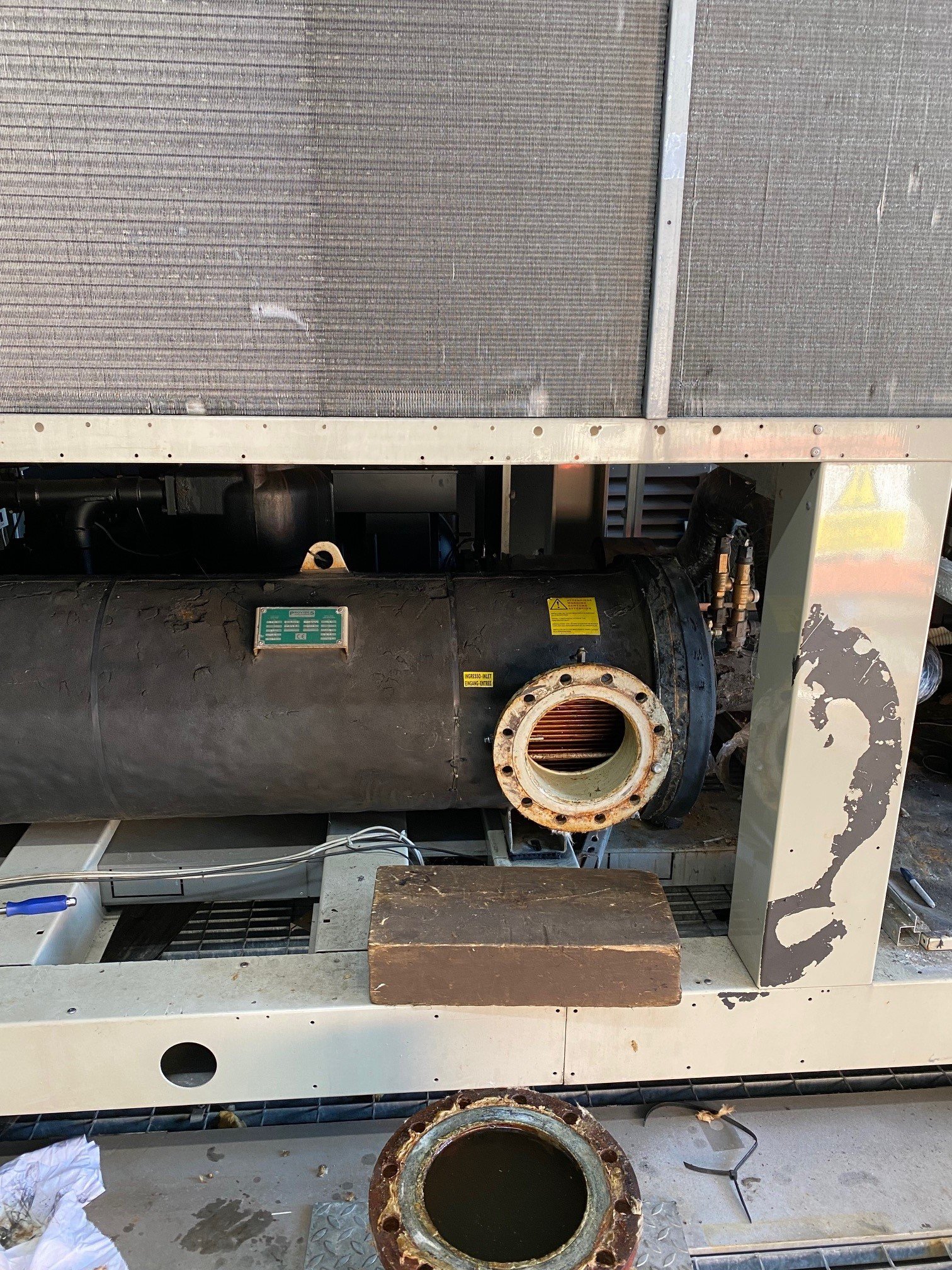

Replaced evaporator, compressor and oil separator due to the evaporator failing causing chilled water to get into the refrigerant system

Klimatec was asked to replace a failed evaporator and compressor.

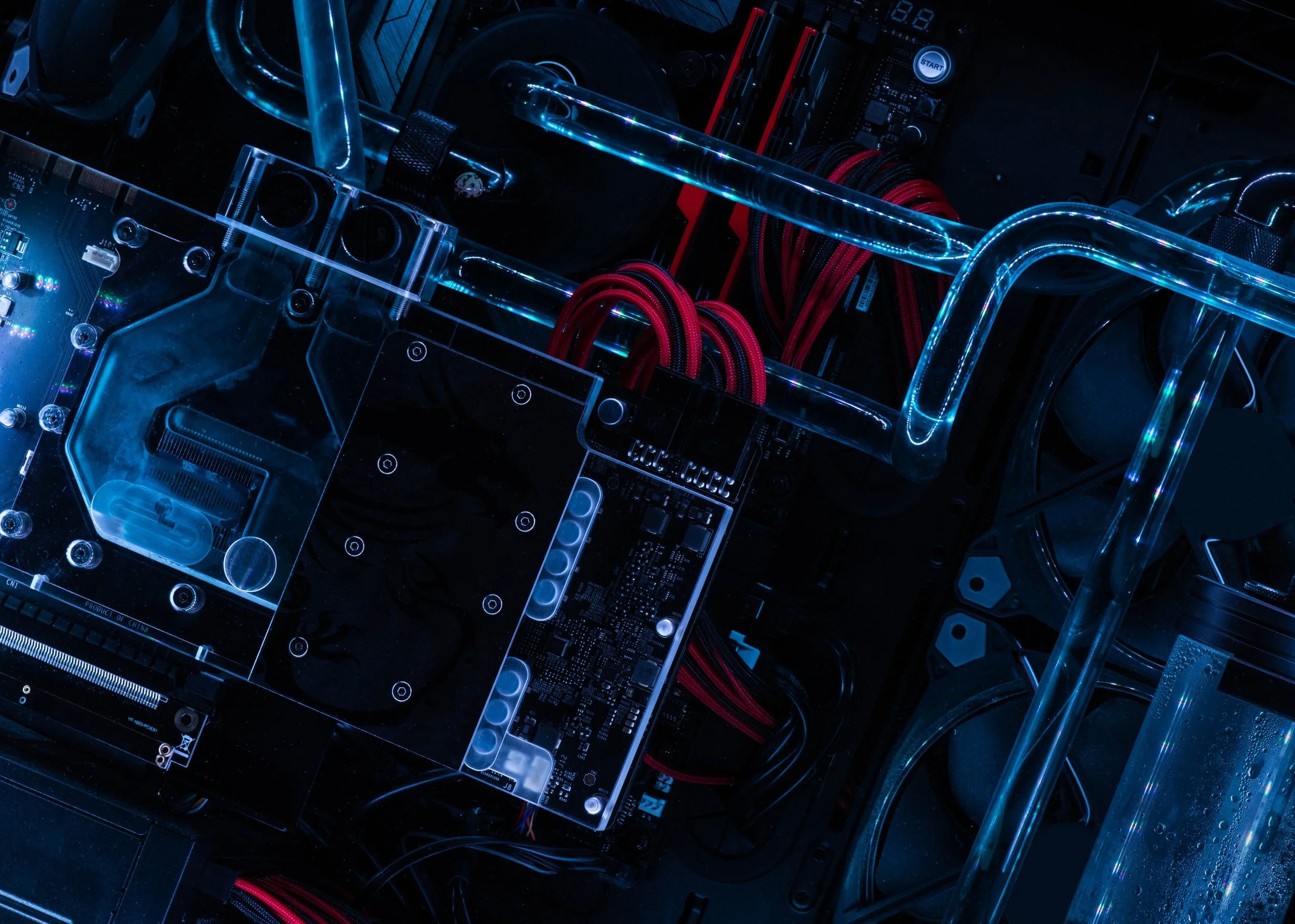

The chiller was isolated whilst maintaining cooling from the other chiller’s serving the data hall.

After decommissioning the circuits and with the use of lift and shift methods we were able to safely get the two components into a position where they could be craned off the roof.

We then used the same lift and shift methods to install the evaporator and compressor.

Replaced failed evaporator and compressor

The client’s evaporator tubes were leaking across to the refrigerant side

Maintained cooling for the client during the replacement due to the nature of the premises

Used lift and shift techniques to manoeuvre components

Crane hired to help lift evaporator and compressor

Had to remove all moisture from the system with use of a vacuum pump

Once the parts had been installed, it was a case of reconnecting all pipework for each circuit, pressure testing with OFN and removing any moisture from the system with the use of a vacuum pump.

Each circuit was then re-charged with the recovered refrigerant and virgin for circuit one.

The circuits were then test run and the chiller put back into service.